The use of industrial hoses is essential in the field of hydraulics. These devices enable machines and systems to move, transfer, and maneuver liquids with high efficiency.

But what exactly are industrial hoses? How do they work? And how have they impacted the field of hydraulics over time?

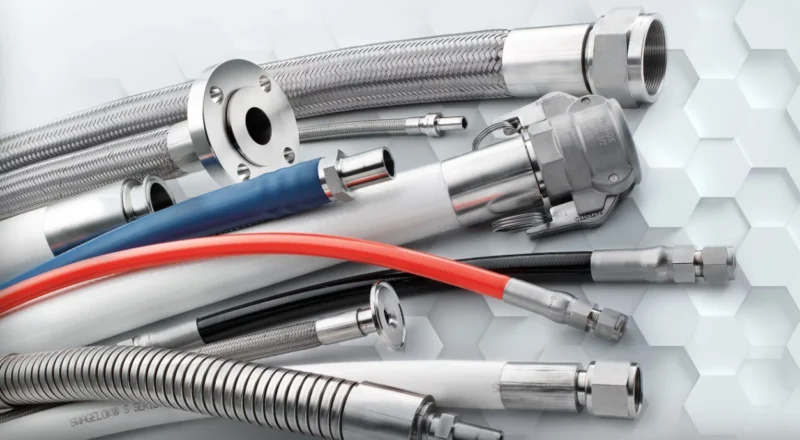

This article takes a detailed look at these questions, exploring the history and development of industrial hoses as well as their current role in hydraulic applications. From components such as tubing to couplings, we cover all aspects that make up this important tool.

We also discuss some potential areas for improvement in terms of safety and cost-effectiveness. Read on for an insightful overview of the impact that industrial hoses have had on the world of hydraulics!

Overview of Industrial Hoses and Their Impact

Industrial hoses are an essential part of many hydraulic systems, offering flexibility and durability. Their ability to withstand extreme temperatures, pressures, and chemical environments makes them ideal for a wide range of applications.

Moreover, they have become increasingly popular due to their cost-effectiveness as well as the ease with which they can be installed or replaced. With advances in design features such as reinforced walls and electrically conductive plastics, industrial hoses are now even safer than ever before.

Ultimately, these versatile components greatly improve efficiency by providing reliable connections between machines/equipment & power sources while ensuring maximum safety at all times – making them an integral component in today’s advanced hydraulic system designs & implementations!

Benefits of Using Industrial Hoses in Hydraulic Applications

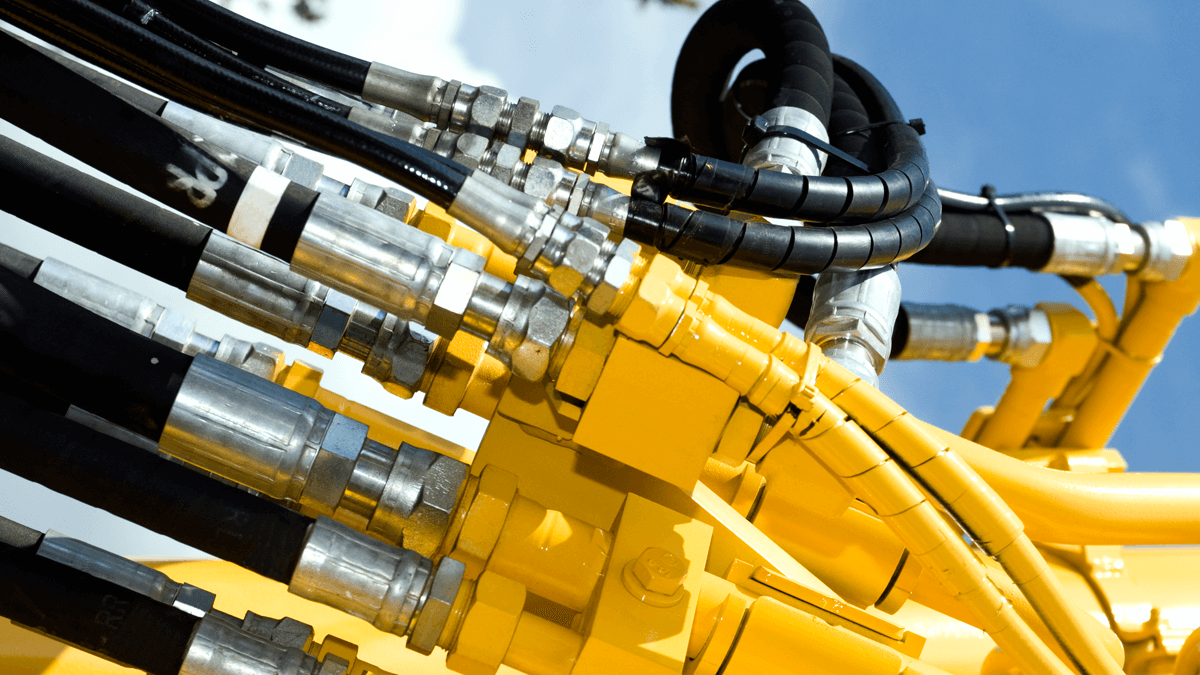

The use of industrial hoses in hydraulic applications has several benefits. This includes improved efficiency, enhanced safety, and greater flexibility when connecting machines and power sources.

In addition to this, they are also designed to be resistant to corrosion and abrasion which makes them long-lasting components that require minimal maintenance over time. Furthermore, their robust construction allows them to withstand high-pressure levels while providing superior filtration capabilities for better system protection against contaminants.

Finally, due to the wide range of sizes available on the market, it is possible to find an appropriate industrial hose solution for virtually any application need – making them a versatile and cost-effective way to optimize your hydraulic systems performance!

Challenges Encountered When Utilizing Industrial Hoses

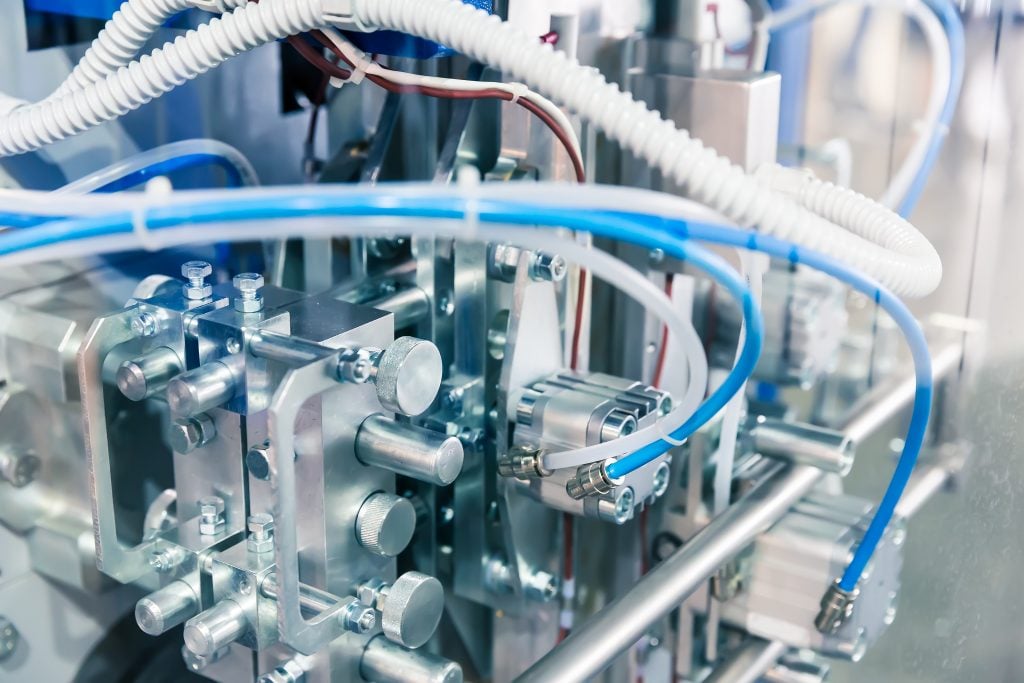

One of the challenges encountered when utilizing industrial hoses is compatibility issues. It is important to ensure that all components are compatible with one another and that they will work together in harmony.

This includes making sure that fittings, connections, clamps, and other accessories meet the required specifications so as not to cause any damage or system failure. Additionally, it’s also important to factor in environmental conditions such as temperature range or pressure levels when selecting an appropriate hose for a particular application.

Furthermore, improper installation can also lead to problems down the line due to kinks or weak seals which may reduce flow rate efficiency or even lead to leaks if not properly addressed quickly.

Lastly, regular maintenance checks should be conducted on all equipment connected via these hoses to make sure everything is performing optimally and safely at all times.

Conclusion

Industrial hoses have been a vital part of the hydraulics field for decades. They are used in various applications and provide many benefits, such as durability and flexibility.

Rent One Hose is a leading industrial hose manufacturer that supplies high-quality products to customers all around the world. Their range of products can be used for a variety of purposes from powering hydraulic machinery to carrying water or other liquids.

If you’re looking for an efficient solution to power your hydraulic systems, then industrial hoses from Rent One Hose are a perfect choice. With their comprehensive selection and superior quality materials, they will ensure your system remains up-to-date with the latest technology while providing long-lasting performance and reliability.